Boiler selection

Features

Dimensions

Fuel

Photos

Boiler selection

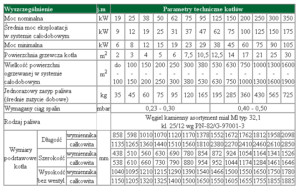

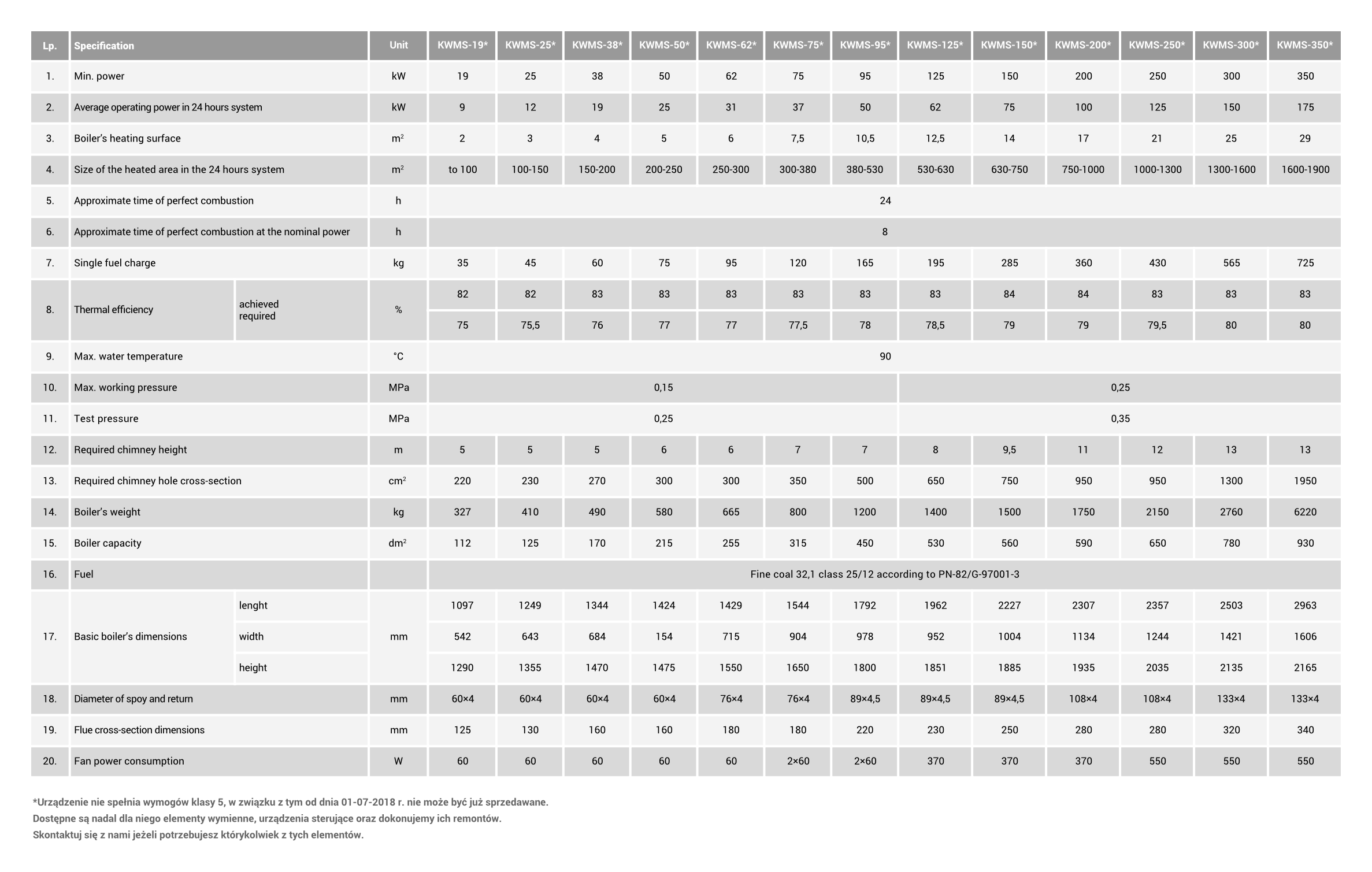

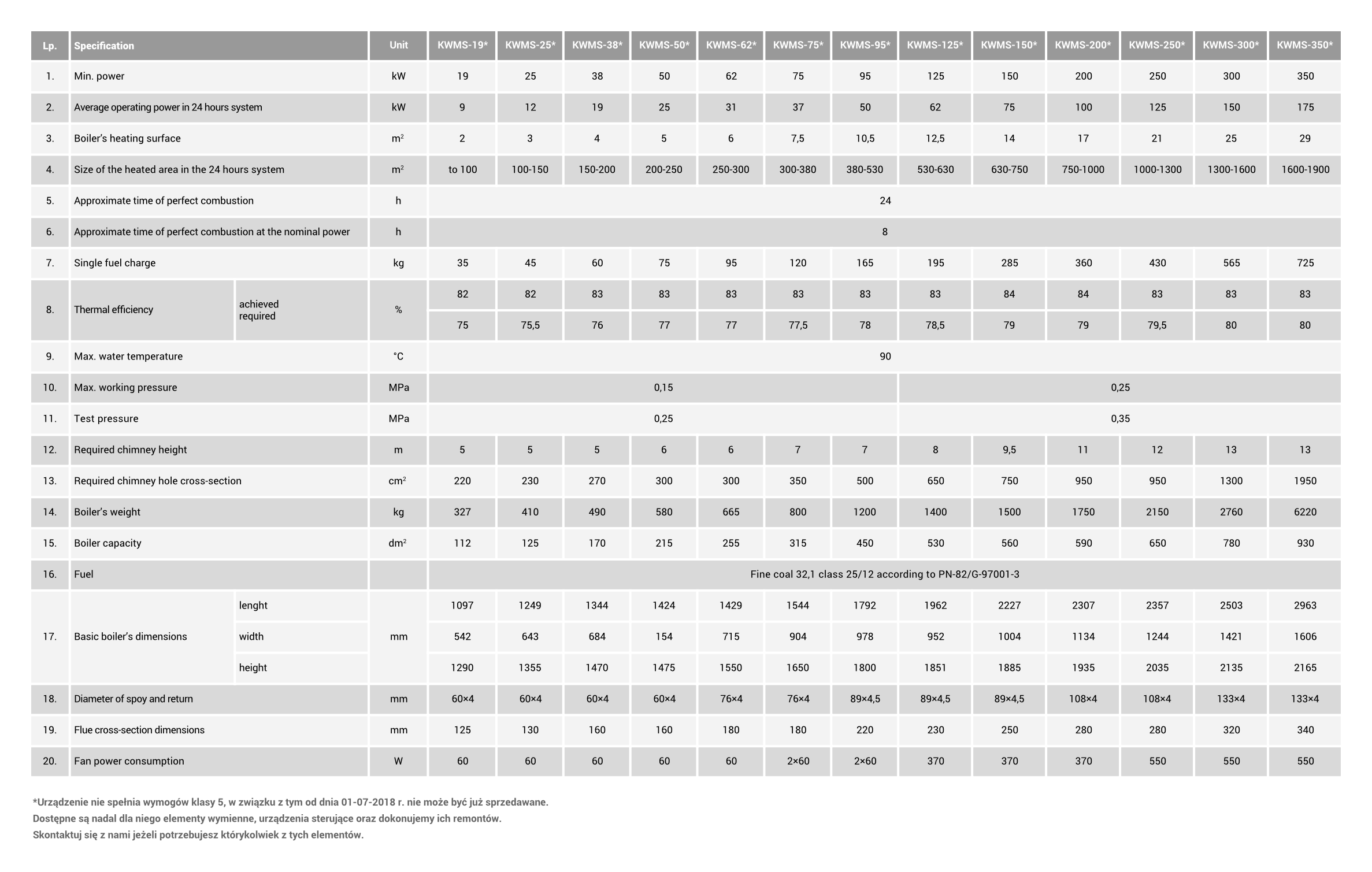

Base for appropriate boiler selection is a thermal balance of the heated area created according to thermal standards for buildings. The nominal thermal efficiency should equal or be little higher (about 10%) than calculated heat requirement of the heated area. In chart nr 2, No. 4 are information about size of area that can be heated by KWMS boilers. Given data is approximate and is specified for rooms of 3m height.

Features

KWMS heating boilers have certification of compliance with energy efficiency criterion.

Emission and energy tests were conducted by:

Institute of Heating and Sanitary Technology in £ód¼.

Institute for Chemical Processing of Coal in Zabrze.

KWMS heating boilers are designed to heat water in the central heating systems to the temperature not exceeding 900 °C at the boiler’s outlet. KWMS heating boilers are designed for heating living quarters, warehouses, commercial halls, workshops, farm buildings, glasshouses, schools etc. They are used in the central heating system and central hot water systems (gravitational or induced systems). Open in a new tab

Open in a new tab

Open in a new tab

Open in a new tabDimensions

Fuel

Type of fuel recommended for KWMS boilers was given in No. 17 in the chart below. Use of lower quality fuel than recommended will result in thermal efficiency drop. Fine coal should be wet before use.

Photos